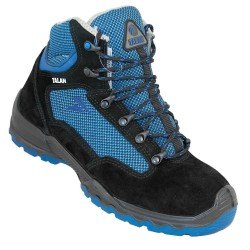

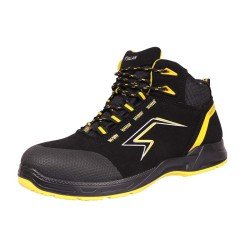

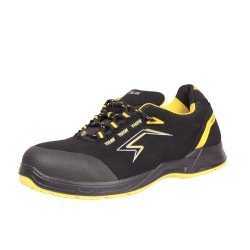

AirFlex Boots Blue

- Completely metal-free

- Upper fabric HT PET with nylon thread, microfiber

- Cordura® textilе tongue

- Spig Tex and Mesh combined lining

- Removable insole with Shock Absortion properties

- Kevlar antistatic MaxFlex ESD midsole

- fiberCap for less weight with perfect protection

- Antistatic, oil-resistant, slipresistant PU-TPU

- Grip control sole from BASF®, with Flex-zones,

- Shock Absortion AirBag System

- staBene last for more comfort

- Reflective insterts

Upper materials

Upper material is made according to the Eco Friendly environmental

standard. The fabric is based on a very strong nylon thread in

combination with a thread made of recycled PET. It penetrates the

material evenly and has no additional coating that can deteriorate

during operation. It is a very strong and at the same time light

material. HT PET provides the best textile benefits in terms of

breathability and wear resistance.

Wear resistance of upper materials

Our laboratory studies have shown that while the strongest fabric has an

average abrasion resistance of 51,000 cycles, this revolutionary HT PET

material reaches up to 1 million cycles! At the toe and heel part of

the shoe Microfiber MICRO1949 is used. It is a high-strength protective

material with a high breaking load. Given that the allowable rate of

rupture is 51,000 cycles, laboratory studies have shown that this

material can withstand 100 thousand cycles, and therefore provides

additional protection against abrasion and rupture.

Outsole

The new modern Grip control outsole provides the optimal combination of

safety and comfort even during active use of shoes. The intermediate

layer of polyurethane has antistatic additives, and the shock-absorbing

properties dampen energy at intensive loadings. The running layer is a

special composition of TPU, which also has antistatic properties. Thanks

to modern technologies we have reached the optimal weight of the

outsole, which directly affects the weight of all shoes. No less unique

is the new development of the outsole. 85% of the tread is made of small

triangles of equilateral shape, the edges of which are directed in

different directions. This controls the foot position on a slippery or

uneven surface. Each edge of such a triangle confidently restrains

sliding in any direction. The front part of the outsole is divided into

flex-zones to facilitate movement. The heel part has an optimal contact

area with the surface, which provides better balance in a static

position or in motion.

Water resistance

Thanks to the structure and special processing of HT PET material, the

shoe has waterproof properties in accordance with S3 standards. The

material density prevents water from penetrating the shoe. The steam is

excreted at the molecular level – the foot breathes well, does not

sweat, and therefore a sense of comfort accompanies the employee for a

long time.

Shoe weight

According to our marketing research, all employees have a general need

for lighter and more comfortable shoes, because they work in it for a

long time. Usually, work shoes are less comfortable than everyday ones,

so workers get tired faster. This is what inspired us to create a new

series of AirFlex work safety shoes. The production of these shoes uses

new technologies and modern materials that make the shoes even lighter.

This provides a reliable level of protection and comfort for a long

working process. The weight of the half-pair is around 490 grams.

Аmortization

Shock Absortion insole is a unique molded insole, complemented by

comfortable properties, namely: soft Shock Absortion inserts on the foot

support points and a silicone insert in the heel for greater walking

comfort.

The outsole has shock-absorbing properties. An

intermediate layer of foamed polyurethane dampens energy during walking

and exercise. Feel confident and comfortable in any situation and under

any conditions! Thanks to the special recipe, the chemical composition

of the intermediate and outer layers of the sole, and with the help of

modern technologies, we have achieved flexibility and optimal weight of

the outsole, which directly affects the weight of all shoes.

Shock Absortion system: the heel part in of the midsole contains a

shock-absorbing part with a permanent grip of 15 bar, made of special

shock-absorbing fibers AirBag. Elasticly stretched fibers are pulled

together inside the sealed AirBag. This detail softens the step and

makes the foot movements smooth, absorbs the shock load when jumping

from a height and reduces the load on the back by dampening excess

energy, promotes better contact of the foot with the surface,

stabilizing each step.

Toe cap

Protective, lightweight composite Toe cap of the new generation Toe

Cover. Given the anatomical features of human foot, this cap has been

designed to provide the shoes with enough free space. This reduces

discomfort and compression of toes during use, especially under intense

loads for a long time. Protects toes from impact by 200 Joules. Made in

Italy.

*200 J – this energy reserve has a weight of 20.52 kg, falling from a height of 1 meter.

The reflective part is sewn into the side of the berets for safety in poorly lit areas. This is especially true when working in large warehouses, where there are many “blind” areas, so that a car driver car has time to respond to the presence of another warehouse worker; at inspection stations, gas stations, etc.

| Certifications | |

| Protection class | S3 |

| Upper | |

| Upper | fabric HT PET with nylon thread, microfiber |

| Lining | Spig Tex and Mesh combined lining |

| Footbed | Removable insole with Shock Absortion properties |

| Sole | PU/PU | BASF® |

| Toe cap | Fiber toe cap |

| Midsole | Kevlar midsole |